Small Home Gazette, Summer 2015

Molasses: A Sweet Solution for Rust Removal

Wandering into an antique store packed full of delights around every corner, you can discover objects you never imagined needing, which can lead to projects you’d never dreamed of doing. That’s how I ended up soaking two cast iron planters in molasses.

When I arrived early to the King Boreas Grande Day Winter Carnival Parade in St. Paul in January, I decided to look around antiques shops on West Seventh Street while waiting for the marching bands. Wescott Station Antiques was friendly and invited exploration of its six jam-packed rooms of random treasures. Tucked in an alcove I discovered two rusty cast iron planters that I suddenly had to have for my garden.

When I arrived early to the King Boreas Grande Day Winter Carnival Parade in St. Paul in January, I decided to look around antiques shops on West Seventh Street while waiting for the marching bands. Wescott Station Antiques was friendly and invited exploration of its six jam-packed rooms of random treasures. Tucked in an alcove I discovered two rusty cast iron planters that I suddenly had to have for my garden.

Rust Away

I loved the aged look of the planters but didn’t want my newly purchased urns to rust away. An Internet search yielded lots of options for rust removal. I could choose quick removal with harsh chemicals like phosphoric or oxalic acid, though they can harm skin. Sanding can damage the metal, and home electrolysis seemed too complicated.

Choosing an environmentally friendly route meant I could use household products like vinegar, lemon juice or baking soda. And it turns out that numerous guys who restore cars—from hot rods to Model Ts—touted molasses as a safe, reliable option for cleaning parts, big and small, down to bare metal. These guys actually submerge entire car doors in molasses baths. A YouTube video (http://tinyurl.com/nj86wkl) demonstrates the process well.

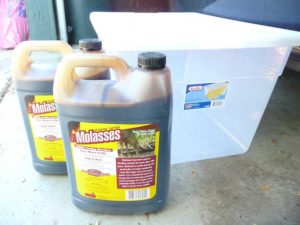

Molasses seemed like a sweet solution for my rust removal. It removes rust through the chemical reaction of chelation. The iron oxide (rust) binds with molecules in the molasses, leaving your metal rust free. Any molasses can do the job, but I saved my Brer Rabbit Molasses for baking and purchased the much cheaper animal grade molasses at Fleet Farm, sold by the gallon. I next picked up a 14-gallon plastic storage box, with lid, to serve as my vat.

Molasses seemed like a sweet solution for my rust removal. It removes rust through the chemical reaction of chelation. The iron oxide (rust) binds with molecules in the molasses, leaving your metal rust free. Any molasses can do the job, but I saved my Brer Rabbit Molasses for baking and purchased the much cheaper animal grade molasses at Fleet Farm, sold by the gallon. I next picked up a 14-gallon plastic storage box, with lid, to serve as my vat.

Non-Toxic Soup

I conducted my experiment in the garage because of space, possible spills and potential for odor. Warmer temperatures and stronger molasses concentrations reportedly accelerate the rate of rust removal. I conducted my experiment in early June when daytime temperatures were in the low 60s. Suggested molasses ratios varied from 3:1 to 10:1, water to molasses. Since I had two gallons of molasses, I ended up with a 5:1 ratio once I added enough water to submerge the urns.

Dry, frothy foam burst from the vat of molasses as fermentation starts after a few weeks. Smells like cookies.

After about two weeks, fermentation foam pushed open the lid of my vat. The frothy foam was dry and easy to clean away. A few days after the foam started, the smell of fermentation began. I checked the urns, and they were completely rust free. I was in no hurry to paint as I’d read that you can leave cast iron and steel to soak as long as you want, as the process only affects the rust and not the underlying metal. But the fermentation odor grew stronger and by day 15, my husband Pete demanded I deal with my project as the smell was getting inside his car.

On day 16, I processed the urns one at a time. Wearing rubber gloves to keep my hands clean, I hauled an urn onto the lawn and rinsed it with water from the hose. I rubbed off the lightly clinging scum with a towel and soft steel wool. The urn looked fantastic. Every nook and cranny was 100 percent rust free. I immediately dried the urn—first with a towel, followed by a hair dryer—to minimize flash rust (rust that forms almost instantaneously). Once dry, I spray painted it with a protective Rust-Oleum primer. I repeated the process with the second urn. Over the next couple of days, I spray painted them with Rust-Oleum paint, thoroughly covering all sides of the urns and allowing the paint to dry completely between coatings.

Sweet Sucrate

Now I had a vat of stinky molasses to deal with. The molasses mixture is considered nontoxic, and I discovered iron sucrate (iron oxide’s sweeter cousin) is used in landscaping and organic farming to boost photosynthesis and enhance greening without increasing plant growth. How is iron sucrate made? It’s made by blending iron oxide with sugars, generally molasses.* Armed with this science, I poured half of my molasses stew into my compost pile. I’d read that the mixture could last many months and still be used to remove rust, so I kept the other half, thinking I must have other rusty items I could rejuvenate.

A couple of cautions from my research. First, paint can be damaged in a molasses bath, and zinc die cast metal can dissolve. Second, be aware of the potential odor. Every now and then we still get a waft of fermented molasses from the compost pile. Maybe I need to turn it a little more often.

But in the end, my urns look terrific. If you want to try out molasses for rust removal, feel free to send me a message via the Twin Cities Bungalow Club facebook page. I might even pass on my starter kit to you. Happy rust removal!

| Supplies | Cost |

|---|---|

| Plastic storage box with lid | $ 6.89 |

| Molasses gallon x 2 (7.89 ea.) | $15.78 |

| Primer spray paint | $ 6.99 |

| Finish spray paint x 2 (5.77 ea.) | $11.54 |

| Steel wool, grade #00 | $ 3.99 |

| Rubber gloves | $ 4.99 |

| Total | $50.18 |

* Irony in Iron, Dave Nowakowski, Front Porch Blog, July 20, 2012, www.harrells.com/blog/iron-in-iron.